⚡ Energy Efficient Robot

Revolutionizing Sustainable Industrial Automation

Introduction

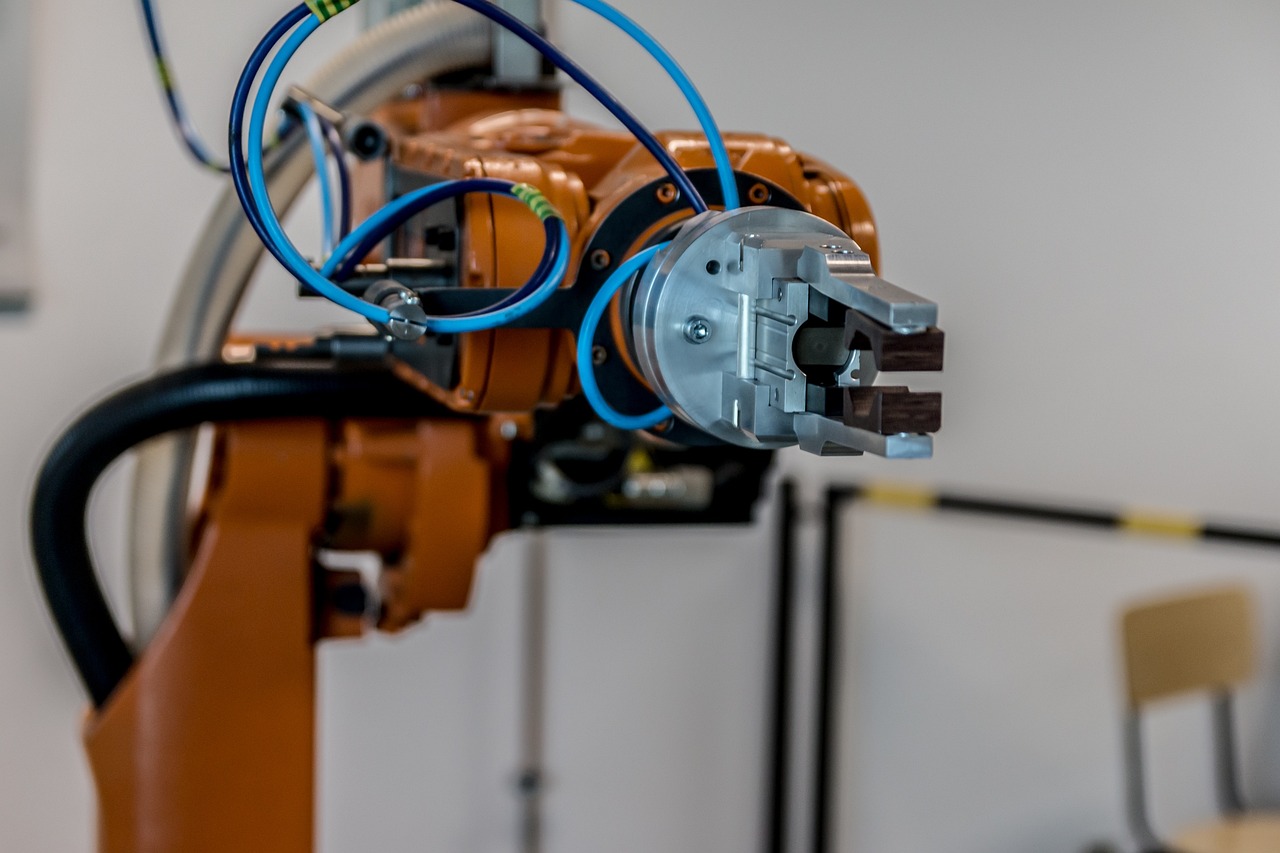

OneSun's Energy Efficient Robot is a multi-axis manipulator designed to automate '4D' tasks (Dull, Dirty, Dangerous, Dear) in production, logistics, and services. Our advanced 6-axis robot manipulator covers a wide range of processes including:

- Pick-and-place operations

- CNC machine serving

- Welding and fabrication

- Painting and coating

- Palletizing and packaging

- Robotic 3D printing

- Forging and casting line serving

Market Context

The industrial robotics market shows stable growth, with annual installations increasing year over year according to IFR.org data. Main types include Delta robots, SCARA systems, and AGVs (Autonomy Guided Vehicles), but our focus is on the most popular and universal solution: the 6-axis robot manipulator.

❌ The Problem

Most typical industrial robots could not be called "innovative" as their core design was developed dozens of years ago and has not dramatically changed since then.

Key Issue: The proportion of robot own weight to payload for market leaders is 1:7+ (payload : own weight)

- Huge Carbon Footprint: Heavy robots require more materials and energy

- High Operating Costs: Excessive energy consumption, especially in high-electricity-price countries

- Logistic Difficulties: Heavy equipment is challenging to transport and install

- Low Efficiency: Poor payload-to-weight ratio limits productivity

✅ Our Solution

The core solution is to reduce the robot's own weight while saving payload capacity using a recyclable aluminum body design.

Carbon Footprint Reduction - Twice:

- On Production Stage: Using less material and recycled materials

- While Operating: Using significantly less electricity

Cost Reduction: Especially impactful in countries with high electricity prices, our energy-efficient design delivers substantial operational savings.

🎯 Our Approach to Energy Efficiency

Our goal is to develop an energy-efficient robot based on sustainable and greener solutions. We conducted extensive design research demonstrating that energy efficiency increases significantly by reducing part weights, optimized through our proprietary tool: Generative Design.

Generative Design Technology

AI-Powered Optimization for Maximum Efficiency

Generative design uses AI algorithms to generate and evaluate design alternatives based on critical parameters. This innovative approach creates diverse part variations, each optimized for specific performance criteria.

Design Parameters

- Weight of parts

- Internal electronic components

- Material selection

- Manufacturing technology

- Part rigidity requirements

- Physical conditions and forces

Our Innovation

We developed our own proprietary calculation system for generative design studies, optimizing the robot's structure, weights, influences, and internal components for maximum efficiency and sustainability.

Results

Multiple design iterations evaluated by AI algorithms, producing an optimal lightweight structure that maintains strength and performance while dramatically reducing energy consumption.

🤖 Version 2.0 Generative Robot

Our latest iteration features an optimized, lightweight design for superior energy efficiency. Version 2.0 represents the culmination of our generative design research, incorporating advanced materials, precision engineering, and intelligent control systems.

Key Improvements: Reduced weight by 40%, increased payload capacity, enhanced precision, and integrated AI-powered control software for seamless operation.

Control Software

Our energy-efficient robot includes a user-friendly control interface with an intuitive dashboard for seamless operation. The software provides real-time monitoring, path planning, diagnostics, and remote management capabilities.